Biogreenline: Überlagerte Lebensmittel entpacken für neues Leben

Wir schliessen den Kreislauf von Natur und Wirtschaft.

Organische Abfälle sind in unserer modernen Welt unvermeidbar. Das gilt auch für Verpackungsmaterial, das mit organischen Abfällen einhergeht. Unsere Mission ist es, beides auf effiziente Art wieder nutzbar zu machen. Denn in jedem Gramm dieser Abfälle steckt Energie, die wir in den wirtschaftlichen und natürlichen Kreislauf zurückführen können. Biogreenline steht dafür, überlagerte Lebensmittel effizient zu entpacken, für neues Leben. Für die Wertschöpfung Ihres Unternehmens. Und unsere Umwelt.

Separatoren: VS-Serie

Für die Trennung von Verpackungen und organischen Inhalten in grossen Mengen.

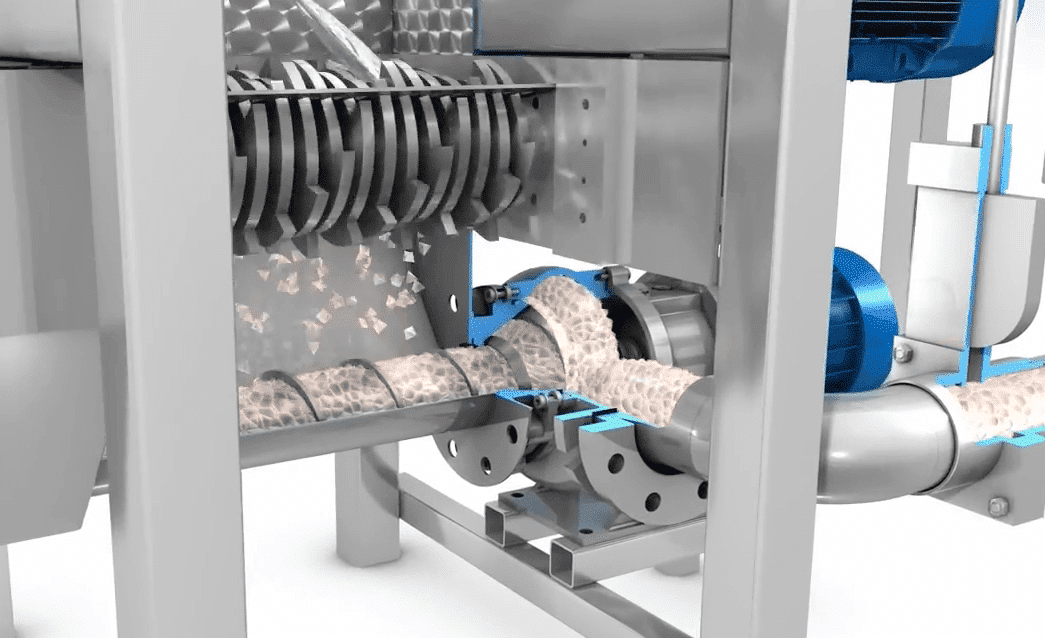

Fisch- /Gemüse-Schredder

Dank einer speziell für robuste Fisch- / Gemüseabfälle optimierten Zahnform verarbeiten unsere Schredder die Produktionsreste schnell und störungsfrei.

Lösungen

Nachhaltige Lösungen bestehen aus mehr als nur der Anschaffung der richtigen Maschine. Deswegen planen wir Ihr Waste Management-System auf Wunsch gleich von Anfang an mit Ihnen – von der Bedarfsanalyse und Planung über die Systemintegration bis zur Inbetriebnahme und Wartung. So profitieren Sie uneingeschränkt von der Expertise, die wir weltweit bei über 70 realisierten Projekten gesammelt haben.

Beratung

& Planung

- Bedarfsanalyse

- Strategie

- Begleitung der regionalen

- Abfallplanung

- Regulation

- Bauplanung

- Betriebskonzept

- Finanzierung

- Schulung

- Integration in Biogasanlagen

Gesamtanlage

& Systemintegration

- Projektmanagement

- Komponentenbeschaffung

- Engineering

- Systemintegration

Ersatzteile

& Unterhalt

- Originalersatzteile

- Ersatzteilmanagement

- Installation

- Inbetriebnahme

- Reparatur und Unterhalt

- Fernsupport durch Ferndiagnose

Bekämpfen Sie Foodwaste mit System.

Der geschlossene Kreislauf - Prozess beginnt mit einer sauberen Trennung.

Der Prozess der möglichst effektiven Trennung von Verpackung und Inhalt ist für eine effiziente Wertschöpfung von entscheidender Bedeutung. Wir haben in den letzten zehn Jahren eng mit unseren Kunden zusammengearbeitet, um eine bewährte Trenntechnik zu entwickeln, die wegweisend ist und neue Standards weltweit setzt. Was Sie davon haben: maximale Nachhaltigkeit und Wirtschaftlichkeit mit weniger synthetischen Abfällen. Unterstützt Sie verpackte Lebensmittel mit zu recyceln.

So funktioniert's

Synthetische Stoffe wie Plastik werden mit minimalen Biomasse-Rückständen ausgesondert.

Die restliche Menge wird in Verbrennungsanlagen ebenfalls zu Energie.

Je nach Zusammensetzung der synthetischen Stoffe können diese recycelt werden.

1

2

3

4

Lebensmittelabfälle aller Art werden mechanisch in organische und synthetische Stoffe getrennt.

Die organischen Abfälle werden maschinell zu Biosubstrat ohne Rückstände von Plastik und anderen Störstoffen verarbeitet.

Pro Tonne Biosubstrat werden in Biogaskraftwerken bis zu 850 kWh saubere Energie gewonnen.

Das vergorene Substrat aus der Biogasanlage bildet einen hervorragenden und plastikfreien Dünger für die Landwirtschaft.

Nachhaltig

Dank der effizienten Trennung kann ein Grossteil der verpackten Bioabfälle wieder nutzbar gemacht werden. Dies ist unser Beitrag für einen sauberen und nachhaltigen Planeten.

1000 kg

Lebensmittelabfälle

=900 kg

Biogas / Biodünger / Recycling

=100 kg

Verpackungen und Reststoffe

90%

der Abfallmenge wiederverwertet

Günstig

Der Verpackungsmüll wird auf einen Bruchteil des vorherigen Volumens reduziert. Biogas und Biodünger generieren neue Einnahmen. Das Resultat sind deutlich tiefere Entsorgungskosten.

CHF 120/Tonne

konventionelle Abfallentsorgung

75%

der Abfallmenge wiederverwertet

Rentabel

Mit den Kosteneinsparungen erzielen unsere Kunden bei einer Laufleistung von über 10 Jahren einen hervorragenden Return on Investment.

400%

ROI über gesamten Lebenszyklus