Biogreenline a new life for expired food

Biogreenline close the natural and economic cycle of food

Biogreenline Organic waste is unavoidable in our modern world. That also applies to packaging material that is associated with organic waste. Our mission is to make both usable again in an efficient manner. That’s because every gram of this waste contains energy that we can return to the economic and natural cycle. Adding value to your company. And our environment.

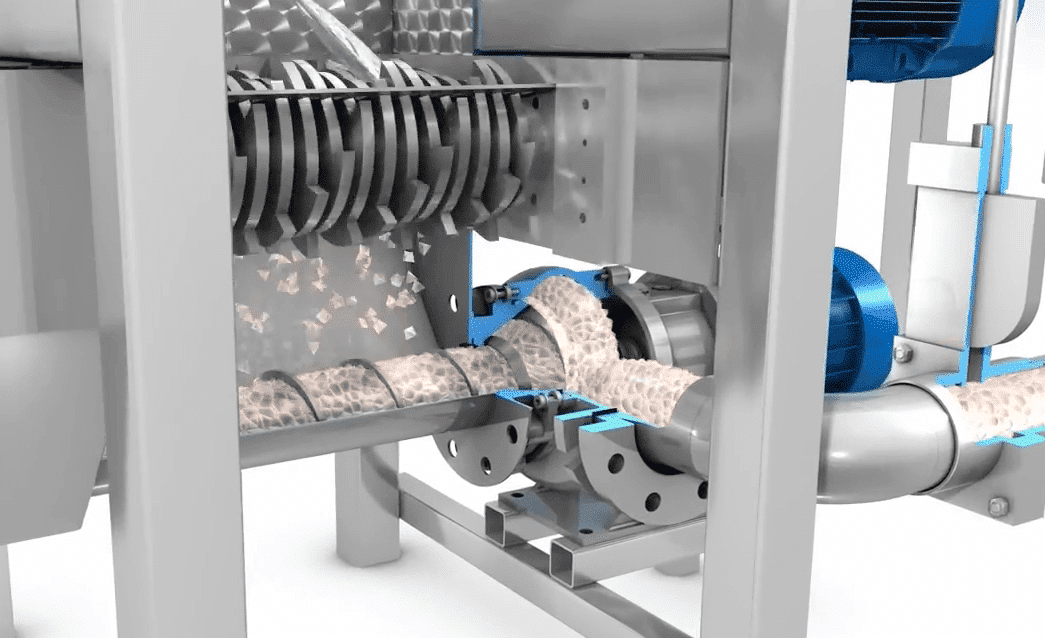

Separators: VS-Series

For the separation of packaging and organic waste in large quantities.

High-tech in today's fish and vegetables shredders

Thanks to a tooth shape specially optimised for robust waste, our shredders process the production residues and trouble-free.

Solution of Bigreenline

Biogreenline your partner for food waste separation

Sustainable solutions mean more than just getting the right machine. That is why we can plan your Waste Management System together from the start – from the requirement analysis and planning through system integration all the way up launch and maintenance. That way, you will have full access to the expertise we have gathered along the way from over 70 implemented projects around the globe.

Consultation

& Planning

- Requirement assessment

- Strategy

- Regional waste planning support

- Regulation

- Project planning

- Operating concept

- Financing

- Training

- Integration into biogas plants

Overrall system

& System integration

- Project management

- Component procurement

- Engineering

- System integration

Spare parts

& main tenance

- Original spare parts

- Spare parts management

- Installation

- Launch

- Repair and maintenance

- Remote support through diagnostics

With Biogreenline you fight food waste with a system

Closing the loop starts with a clean Separation

The key to effective value creation lies in the most efficient separation of packaging and content. Over the last ten years we’ve worked closely with our customers and developed a ground-breaking separation technique that sets new standards worldwide. How do you benefit: a minimum of synthetic residual materials combined with maximum sustainability and profitability.

How the Process works

Synthetic materials, like plastic, undergo separation with minimal presence of biomass residues.

Residual materials are further converted into energy through incineration processes.

Recycling is possible based on the composition of synthetic substances.

1

2

3

4

Waste generated from various food sources is mechanically sorted into organic and synthetic materials.

Mechanical processing transforms organic waste into an organic substrate, ensuring the absence of residues from plastic and other environmentally hazardous substances.

With the organic substrate obtained, a biogas power plant can produce up to 850 kWh of clean energy per ton.

The fermented substrate from the biogas system serves as an excellent, plastic-free fertilizer for agriculture.

Nachhaltig

Effective separation enables the reuse of the majority of packaged organic waste. This is our contribution to a clean and sustainable world.

1000 kg

expired food

=900 kg

biogas / biofertilizer / recycling

=100 kg

packaging and residues

90%

of the waste volume recycled

Günstig

Packaging waste is minimized to a fraction of its original volume, creating new income through biogas and biofertilizers and leading to significantly reduced disposal costs.

CHF 120/Tonne

of conventional waste disposal

CHF 30/Tonne

with disposal using the Biogreenline system

75%

of the waste volume recycled

Rentabel

Our customers experience significant cost savings, ensuring an excellent return on investment with a service life exceeding 10 years.

2-3 Jahre

Ø Time until break even

400%

ROI across entire life cycle